地址:北京市海淀区上地十街1号

电话:15132636097

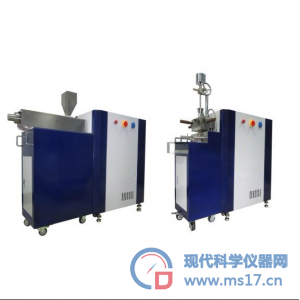

计算机控制转矩流变仪由密炼转矩流变仪、挤出式毛细管流变仪、毛细管测试模头、数据采集测量系统、电子计算机、操作软件等部分组成。

转矩流变仪可以用来研究热塑性材料的热稳定性、剪切稳定性、流动和塑化行为,其最大特点是能在类似实际加工过程中连续准确可靠地对体系的流变性能进行测定,还可以完成热固性材料的固化特性测试。

橡塑材料在加工成型的过程中,几乎都要涉及其流动性。例如,在挤出、注模、吹膜、压延等工艺中,材料的流动行为都是十分重要的。材料的流动性不但影响加工行为,还会影响最终产品的力学性能。例如,分子取向对模塑产品,薄膜和纤维的力学性能都有很大影响。而分子取向的类型和程度主要是由加工过程中流动场的特点和材料的流动行为所决定。

应用领域

1、UPVC加工性能研究及材料开发

2、热塑性材料的开发及加工性能研究

3、交联、热固性树脂固化性能研究

4、教学科研应用

转矩流变仪是研究聚合物材料的流动与变形、塑化、热剪切稳定性、动态流变性能和塑化行为并将结果用扭矩--时间和扭矩--温度等用图表形式表示出来的理想设备,可广泛地应用于科研和生产,是进行科学研究以及指导生产的重要仪器。与研究材料流动性的一般性仪器——粘度计相比,该流变仪提供了更接近于实际加工的动态测量方法,可以在类似实际加工的情况下,连续、准确可靠地对材料的流变性能进行测定,如多组份物料的混合、热固性树脂的交联固化、弹性体的硫化,材料的动态稳定性以及螺杆转速对体系加工性能的影响等。

密炼转矩流变仪:

密炼转矩流变仪主要由进口伺服电机、高精度动态扭矩传感器、齿轮箱、密炼腔、温度模块、测量模块、计算机、测控软件等部分组成。

密闭式混合器相当于一个小型的密炼机,由一个 “∞”字型的可拆卸混合室和一对以不同转速、相向旋转的转子组成。在混合室内,转子相向旋转,对物料施加剪切,使物料在混合室内被强制混合;两个转子的速度不同,在其间隙中发生分散性混合。

本机整体美观,主体钣金采用乳白色与蓝色的配色方案,也可以根据用户的要求颜色处理。不锈钢部分采用SUS304不锈钢。

计算机软件具可数据采集、存储、计算、分析和输出功能,可根据用户要求打印试验报告。

主要技术特性及配置

可以用来研究热塑性材料的热稳定性、剪切稳定性、流动和塑化行为,其最大特点是能在类似实际加工过程中连续准确可靠地对体系的流变性能进行测定,还可以完成热固性材料的固化特性测试。

1. 电机功率:日本松下3.0kw伺服电机

2. 电机转速:3000 rpm

3. 电机驱动器3.0 kw

4. 减速器:1:20进口

5. 动力输出转速:0 ~ 150rpm

6. 转速控制精度:0 .05%F.S

7. 温度控制:5路测温,其中4路控温

8. 静态测量精度:0.1°C

9. 温度控制精度:±1°C

10. 转矩测量量程:0 ~ 250Nm

11. 转矩测量精度:0.1%F.S

12. 熔体压力测量量程:0.1 ~ 100 Mpa

13. 熔体压力测量精度:0.5%F.S

14. 软件:、测控软件、聚合物熔体粘度测量数据处理软件、挤出机数据处理软件、混合器数据处理软件。

15. 图形显示:转速、转矩、温度、压力

16. 电压:AC380V 7.5kw

双螺杆挤出机组主要应用于橡塑和工程树脂的填充、共混、改性、增强、氯化聚丙稀和高吸水性树脂的脱挥处理;可降解母粒、聚酰胺缩聚、聚氨酯加聚反应的挤出,碳粉、磁粉的造粒、电缆用绝缘料、护套料、低烟低卤阻燃型PVC电缆料及各种硅烷交联料的制备等。

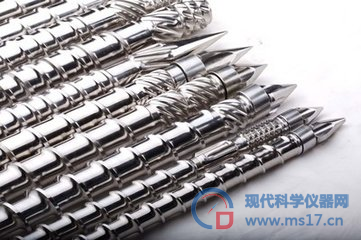

塑料单螺杆挤出机(材料38CrMOALA)(选配、价格另议)

1、L:D: 25:1

2、螺杆直径: φ20mm

3、螺杆压缩比: 2.5:1

4、最高温度: 350℃

5、加热方式: 电加热

6、加热区: 5路

7、加热总功率: 4200W

8、温度传感器: K类热电偶

9、机器体积(长×宽×高): 1600×450×1300(mm)

10、毛细管模具:φ1.27 长径比20:1、30:1、40:1模芯各一

(φ1、φ2等其他规格的可选配、价格另议)

圆柱模头(可选):内径:Ф5,外径: Ф10

system composition

The computer-controlled torque rheometer consists of a mixing torque rheometer, an extrusion capillary rheometer, a capillary testing die, a data acquisition and measurement system, an electronic computer, and operating software.

Applicable scope

The torque rheometer can be used to study the thermal stability, shear stability, flow and plasticization behavior of thermoplastic materials. Its biggest feature is that it can continuously, accurately and reliably measure the rheological properties of the system in similar actual processing processes, and can also complete the solidification characteristic testing of thermosetting materials.

In the process of processing and forming rubber and plastic materials, their fluidity is almost always involved. For example, in processes such as extrusion, injection molding, blow molding, and rolling, the flow behavior of materials is very important. The fluidity of materials not only affects processing behavior, but also affects the mechanical properties of the final product. For example, molecular orientation has a significant impact on the mechanical properties of molded products, films, and fibers. The type and degree of molecular orientation are mainly determined by the characteristics of the flow field during the processing and the flow behavior of the material.

application area

1. Research on Processing Performance and Material Development of UPVC

2. Development and Processing Performance Research of Thermoplastic Materials

3. Research on the Curing Performance of Crosslinked and Thermosetting Resins

4. Teaching and research applications

The torque rheometer is an ideal equipment for studying the flow and deformation, plasticization, thermal shear stability, dynamic rheological properties, and plasticization behavior of polymer materials, and presenting the results in graphical forms such as torque time and torque temperature. It can be widely used in scientific research and production, and is an important instrument for conducting scientific research and guiding production. Compared with the general instrument for studying material flowability - viscometer, this rheometer provides a dynamic measurement method that is closer to actual processing. It can continuously, accurately and reliably measure the rheological properties of materials in situations similar to actual processing, such as the mixing of multi-component materials, crosslinking and curing of thermosetting resins, and vulcanization of elastomers, The dynamic stability of materials and the influence of screw speed on the processing performance of the system.

Internal mixing torque rheometer:

The internal mixing torque rheometer mainly consists of imported servo motors, high-precision dynamic torque sensors, gearboxes, mixing chambers, temperature modules, measurement modules, computers, measurement and control software, and other parts.

A closed mixer is equivalent to a small internal mixer, consisting of an infinity shaped detachable mixing chamber and a pair of rotors rotating in opposite directions at different speeds. In the mixing chamber, the rotor rotates in opposite directions and applies shear to the material, forcing it to be mixed in the mixing chamber; The two rotors have different speeds and exhibit dispersed mixing in their gaps.

The overall appearance of this machine is beautiful, and the main sheet metal adopts a color scheme of milky white and blue, which can also be processed according to the user's requirements. The stainless steel part adopts SUS304 stainless steel.

Computer software has functions for data collection, storage, calculation, analysis, and output, and can print test reports according to user requirements.

1、 Main technical features and configurations

It can be used to study the thermal stability, shear stability, flow and plasticization behavior of thermoplastic materials. Its biggest feature is that it can continuously, accurately and reliably measure the rheological properties of the system in similar actual processing processes, and can also complete the curing characteristic testing of thermosetting materials.

1. Motor power: Panasonic 3.0kw servo motor from Japan

2. Motor speed: 3000 rpm

3. Motor driver 3.0 kW

4. Reducer: 1:20 imported

5. Power output speed: 0~150rpm

6. Speed control accuracy: 0.05% F.S

7. Temperature control: 5 temperature measurement channels, including 4 temperature control channels

8. Static measurement accuracy: 0.1 ° C

9. Temperature control accuracy: ± 1 ° C

10. Torque measurement range: 0~250Nm

11. Torque measurement accuracy: 0.1% F.S

12. Melt pressure measurement range: 0.1~100 Mpa

13. Melt pressure measurement accuracy: 0.5% F.S

14. Software: Measurement and control software, polymer melt viscosity measurement data processing software, extruder data processing software, mixer data processing software.

15. Graphic display: speed, torque, temperature, pressure

16. Voltage: AC380V 7.5kw

The twin-screw extruder unit is mainly used for filling, blending, modifying, strengthening rubber and engineering resins, as well as devolatilization treatment of chlorinated polypropylene and high water absorbent resins; The extrusion of biodegradable masterbatch, polyamide condensation polymerization, polyurethane addition polymerization reaction, granulation of carbon powder and magnetic powder, preparation of insulation materials for cables, sheath materials, low smoke and low halogen flame retardant PVC cable materials, and various silane crosslinking materials.

Plastic single screw extruder (material 38CrMOALA) (optional, price negotiable)

1. L: D: 25:1

2. Screw diameter: φ 20mm

3. Screw compression ratio: 2.5:1

4. Maximum temperature: 350 ℃

5. Heating method: Electric heating

6. Heating area: 5 channels

7. Total heating power: 4200W

8. Temperature sensor: K-class thermocouple

9. Machine volume (length × wide × High: 1600 × four hundred and fifty × 1300 (mm)

10. Capillary mold: φ 1.27 Length to diameter ratio 20:1, 30:1, and 40:1 with one mold core each

( φ 1 φ Other specifications of Class 2 are optional and prices can be negotiated separately

Cylindrical die head (optional): Inner diameter: Ф 5. Outer diameter: Ф ten

我厂主要产品有:

维卡热变形试验仪, 海绵泡沫落球回弹试验机 海绵泡沫压陷硬度测验仪,

海绵泡沫疲劳压陷试验机, 熔融指数仪,

电压击穿试验仪, 塑料球压痕硬度计,

马丁耐热试验仪, 海绵泡沫拉伸强度试验机,

摆锤式冲击试验机, 摩擦系数仪,

拉力试验机, 电子拉力试验机