地址:北京市海淀区上地十街1号

电话:15132636097

欢迎您选用我公司开发研制的各类检测仪器。在使用过程中,如出现什么问题,请及时和我们联系,您将得到良好的售后服务,真诚的希望您能将宝贵的意见,丰富的经验和独到的见解反馈给我们,让我们一起努力,共同提高。

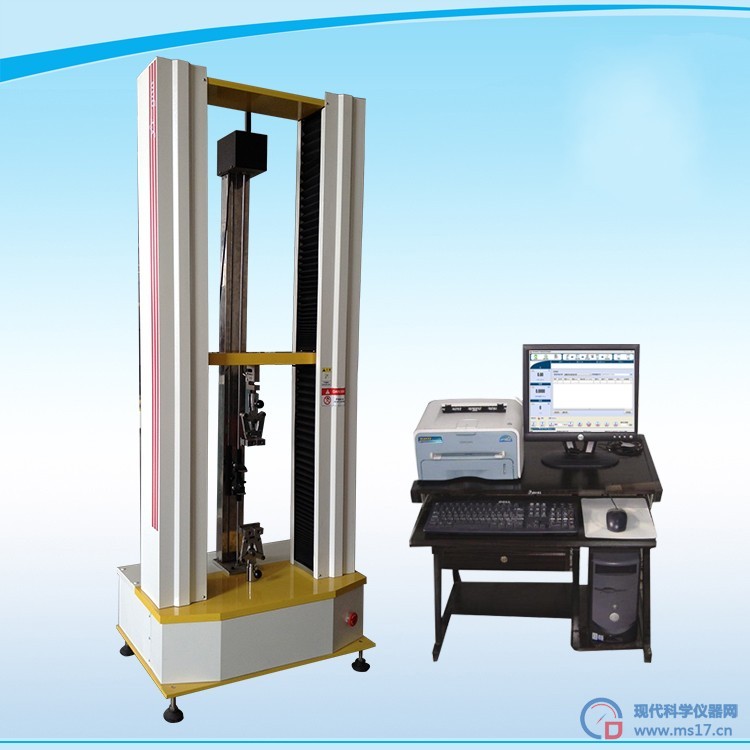

5吨拉力拉伸强度试验机 组成

拉力材料试验机是由测量系统、驱动系统、控制系统及电脑(电脑系统型拉力试验机)等结构组成。

一.测量系统

1. 力值的测量

2. 变形的测量

3. 横粱位移的测量

5吨拉力拉伸强度试验机 驱动系统

主要是用于试验机的横梁移动,其工作原理是由伺服系统控制电机,电机经过减速箱等一系列传动机构带动丝杆转动,从而达到控制横梁移动的目的。通过改变电机的转速,可以改变横梁的移动速度。

三.控制系统

顾名思义,就是控制试验机运作的系统,人们通过操作台可以控制试验机的运作,通过显示屏可以获知试验机的状态及各项试验参数,若该机带有电脑的话,也可以由电脑实现各项功能并进行数据处理分析、试验结果打印。试验机同电脑之间的通信一般都是使用RS232串行通信方式,它通过计算机背后的串口(COM号)进行通信,此技术比较成熟、可靠,使用方便。

四.电脑

用来采集和分析数据,进入试验界面后,电脑会不断采集各样试验数据,实时画出试验曲线,自动求出各试验参数及输出报表。

仪器特点

1、采用高精度、全数字调速系统及精密减速系统,驱动精密丝杠副进行试验,实现试验速度的大范围调节,试验过程噪音低、运行平稳。

2、可选用万向节十字插销结构,一方面便于试样夹持,保证试验同心度,另一方面很好的消除了不规则试样对传感器的影响。

3、Windows操作系统,人性化操作界面,可显示试验方法选择界面、试验参数选择界面、试验操作及结果显示界面和曲线显示界面,并可实时显示各参数曲线,便于试验数据分析,过程监控。测试结果可以WORD、EXCEL格式的数据形式输出,可直接实现试验过程的控制及数据的存储、打印。

4、可实现试样装夹时横梁快慢升降调整,具有过流、过压、过载等保护装置。

Welcome to choose various testing instruments developed and developed by our company. If there are any problems during use, please contact us in a timely manner. You will receive good after-sales service. We sincerely hope that you can provide us with valuable feedback, rich experience, and unique insights, so that we can work together to improve.

form

The tensile material testing machine is composed of a measuring system, a driving system, a control system, and a computer (computer-based tensile testing machine) structure.

1、 Measurement system

1. Measurement of force value

2. Measurement of deformation

3. Measurement of beam displacement

Drive system

Mainly used for the movement of the crossbeam of the testing machine, its working principle is controlled by a servo system to drive the motor. The motor drives the screw to rotate through a series of transmission mechanisms such as a gearbox, thereby achieving the goal of controlling the movement of the crossbeam. By changing the speed of the motor, the movement speed of the crossbeam can be changed.

3、 Control system

As the name suggests, it is a system that controls the operation of the testing machine. People can control the operation of the testing machine through the operating platform, and the status and various test parameters of the testing machine can be obtained through the display screen. If the machine is equipped with a computer, it can also perform various functions and perform data processing and analysis, as well as printing test results. The communication between the testing machine and the computer generally uses RS232 serial communication method, which communicates through the serial port (COM number) behind the computer. This technology is relatively mature, reliable, and convenient to use.

4、 Computer

Used to collect and analyze data, after entering the experimental interface, the computer will continuously collect various experimental data, draw experimental curves in real time, automatically calculate various experimental parameters and output reports.

Instrument characteristics

1. Using a high-precision, fully digital speed control system and precision reduction system, the precision screw pair is driven for testing, achieving a wide range of speed adjustment during the testing process with low noise and smooth operation.

2. The universal joint cross pin structure can be selected, which is convenient for sample clamping and ensures the concentricity of the test. On the other hand, it effectively eliminates the influence of irregular samples on the sensor.

3. The Windows operating system has a user-friendly interface, which can display the interface for selecting test methods, selecting test parameters, displaying test operations and results, and displaying curves. It can also display various parameter curves in real time, making it easy to analyze test data and monitor the process. The test results can be output in WORD and EXCEL formats, which can directly control the experimental process and store and print data.

4. It can adjust the speed of the crossbeam during sample clamping, and has protective devices such as overcurrent, overvoltage, and overload.

技术参数:

1 试验力

醉试验力(kN):2kN

试验机测量精度:1级(标准版)

有效测力范围: 2%-100%FS/

分 辨 力: 1/300000

示值相对误差:±1%

2 试验速度

速度调节范围:0.05~500mm/min(无级调速)/

准确度:优于示值的±1%

力控速率控制范围:0.05—5%FN

力控速率控制精度:速率0.05FN/s时,为±2%设定值以内

速率≥0.05FN/s时,为±1%/

3 位移(移动横梁)

测量范围:0~999mm

分辨率:0.001mm

测量精度:优于示值的±1%

4 试验空间

有效拉伸空间:700mm(或根据用户需要)

有效压缩空间:700mm(或根据用户需要)

有效试验宽度:400mm(或根据用户需要)

5工作环境 室温10~35℃,湿度20%~80%

适用范围:

广泛应用于电线电缆、纺织物、防水材料、无纺布、安全带、橡胶、塑料、薄膜、钢丝绳、钢筋、金属丝、金属箔、金属板材和金属棒丝等金属材料和非金属材料及零部件产品进行拉伸、压缩、弯曲、撕裂、90°剥离、180°剥离、剪切、粘合力、拔出力、延伸伸长率等试验,以及一些产品的特殊力学性能试验。

软件特点:

1、测试标准模块化功能:提供使用者设定所需应用的测试标准设定,范围涵盖GB、ASTM、DIN、JIS、BS…等测试标准规范。

2、试品资料:提供使用者设定所有试品数据,一次输入数据永久重复使用,并可自行增修公式以提高测试数据契合性。

3、 双报表编辑:完全开放式使用者编辑报表,供测试者选择自己喜好的报表格式(测试程序新增内建EXCEL报表编辑功能扩展了以往单一专业报表的格局) 。

4、 各长度、力量单位、显示位数采用动态互换方式,力量单位T、Kg、N、KN、5、lb,变形单位mm、cm、inch。

5、图形曲线尺度自动醉佳化Auto Scale,可使图形以醉佳尺度显示,并可于测试中实时图形动态切换。具有荷重-位移、荷重-时间、位移-时间、应力-应变荷重-2点延伸图,以及多曲线对比。

6、测试结果可以WORD、EXCEL格式的数据形式输出。

7、测试结束可自动存档、手动存档,测试完毕自动求算醉大力量、上、下屈服强度、滞后环法、逐步逼近法、非比例延伸强度、抗拉强度、抗压强度、任意点定伸长强度、任意点定负荷延伸、弹性模量、延伸率、剥离区间醉大值、醉小值、平均值、净能量、折返能量、总能量、弯曲模量、断点位移x%荷重、断点荷重X%位移、等等。

8、数据备份:测试数据可保存在任意硬盘分区。

9、软件具有历史测试数据演示功能。

Technical parameters:

1 Test force

Drunk test force (kN): 2kN

Measurement accuracy of testing machine: Level 1 (standard version)

Effective force measurement range: 2% -100% FS/

Resolution: 1/300000

Relative error of indication: ± 1%

2 Test speed

Speed adjustment range: 0.05-500mm/min (stepless speed regulation)/

Accuracy: better than ± 1% of the indicated value

Force control rate control range: 0.05-5% FN

Force control rate control accuracy: within ± 2% of the set value at a rate of 0.05FN/s

When the rate is ≥ 0.05FN/s, it is ± 1%/

3 displacement (moving crossbeam)

Measurement range: 0-999mm

Resolution: 0.001mm

Measurement accuracy: better than ± 1% of the indicated value

4 Experimental Space

Effective stretching space: 700mm (or according to user needs)

Effective compressed space: 700mm (or according to user needs)

Effective test width: 400mm (or according to user needs)

5. Working environment: Room temperature 10-35 ℃, humidity 20-80%

Applicable scope:

Widely used in metal materials such as wires and cables, textiles, waterproof materials, non-woven fabrics, seat belts, rubber, plastics, films, steel wire ropes, steel bars, metal wires, metal foils, metal sheets, and metal rod wires, as well as non-metallic materials and component products, for tensile, compression, bending, tearing, 90 ° peel, 180 ° peel, shear, adhesive force, pull-out force, elongation, and other tests, as well as special mechanical performance tests for some products.

Software features:

1. Modular testing standard function: Provides users with the required testing standard settings for the application, covering testing standard specifications such as GB, ASTM, DIN, JIS, BS, etc.

2. Sample data: Provide users with the ability to set all sample data, permanently reuse the input data at once, and modify formulas to improve the compatibility of test data.

3. Dual report editing: Fully open for users to edit reports, allowing testers to choose their preferred report format (the testing program has added a built-in Excel report editing function that expands the previous single professional report layout).

4. The length, strength units, and display digits are dynamically swapped, with strength units of T, Kg, N, KN, 5, and lb, and deformation units of mm, cm, and inch.

5. Auto Scale automatically optimizes the graph curve scale, which allows the graph to be displayed at the optimal scale and can be dynamically switched in real-time during testing. Featuring load displacement, load time, displacement time, stress-strain load 2 point extension diagrams, as well as multi curve comparisons.

6. The test results can be output in data formats such as WORD and EXCEL.

7. After the test is completed, it can be automatically saved or manually saved. After the test is completed, it can automatically calculate the maximum strength, upper and lower yield strength, hysteresis loop method, stepwise approximation method, non proportional elongation strength, tensile strength, compressive strength, constant elongation strength at any point, constant load extension at any point, elastic modulus, elongation rate, peeling interval maximum value, minimum value, average value, net energy, return energy, total energy, bending modulus, x% load at break point displacement, X% load at break point displacement, and so on.

8. Data backup: Test data can be saved in any hard disk partition.

9. The software has a historical test data demonstration function.

依据标准

GB/T 16491、GB/T 1040、GB/T 8808、GB/T 13022、GB/T 2790、GB/T 2791、GB/T 2792、GB/T 16825、GB/T 17200、GB/T 3923.1、GB/T 528、GB/T 2611、GB/T 6344、GB/T 20310、GB/T 3690、GB/T 4944、GB/T 3686、GB/T 529、GB/T 6344、GB/T 10654、HG/T 2580、JC/T 777、QB/T 2171、HG/T 2538、CNS 11888、JIS K6854、PSTC-7、ISO 37、AS 1180.2、BS EN 1979、BSEN ISO 1421、BS EN ISO 1798、BS EN ISO 9163、DIN EN ISO 1798、GOST 18299、DIN 53357、ISO 2285、ISO 34-1、ISO 34-2、BS 903、BS 5131、DIN EN 12803、DIN EN 12995、DIN53507-A、DIN53339、ASTM D3574、ASTM D6644、ASTM D5035、ASTM D2061、ASTM D1445、ASTM D2290、ASTM D412、ASTM D3759/D3759M

拉力试验机可对金属、非金属进行拉伸、剥离、压缩、弯曲等力学性能测试和分析研究。可根据GB、JIS、ASTM、DIN、ISO等标准自动求出醉大试验力值、断裂力值、屈服强度、上下屈服强度、抗拉强度、各种伸长应力、各种伸长率、抗压强度、弯曲挠度、弹性模量、定伸长应力、定应力伸长等参数。

拉力试验机广泛用于航空航天、石油化工、机械制造、车辆制造、电线电缆、纺织纤维、塑料橡胶、陶瓷、食品、医药包装、铝塑管、塑料门窗、土工布、薄膜、木材、纸张、金属材料及制品等行业。

普通测试项目:(普通显示值及计算值)

●拉伸应力 ●拉伸强度

●扯断强度 ●扯断伸长率

●定伸应力 ●定应力伸长率

●定应力力值 ●

●任意点力值 ●任意点伸长率

●抽出力 ●粘合力及取峰值计算值

●压力试验 ●剪切力剥离力试验

●弯曲试验 ●拔出力穿刺力试验

维修保养方法及注意事项:

1、机台部份,外表经常擦拭,保持清洁。

2、电镀部份请以机油擦拭,以防止生锈宜保光亮。

3、动力螺杆及螺杆部份请加润滑油,以保传动灵敏。(润滑油采黄油加入少许机油混合即可)。

4、面板(控制箱即显示器)请用乾布擦拭,严防沾水,以免损坏IC电子零件。

5、各项治具及接头配件请妥置,并擦拭防锈油,以防生锈。

6、上下班必需把电源关掉。

The tensile testing machine can test and analyze the mechanical properties of metals and non-metals, including tension, peeling, compression, and bending. According to standards such as GB, JIS, ASTM, DIN, ISO, etc., parameters such as maximum test force value, fracture force value, yield strength, upper and lower yield strength, tensile strength, various elongation stresses, various elongation rates, compressive strength, bending deflection, elastic modulus, constant elongation stress, and constant stress elongation can be automatically calculated.

The tensile testing machine is widely used in industries such as aerospace, petrochemicals, mechanical manufacturing, vehicle manufacturing, wires and cables, textile fibers, plastic rubber, ceramics, food, pharmaceutical packaging, aluminum-plastic pipes, plastic doors and windows, geotextiles, films, wood, paper, metal materials and products.

Normal test items: (Normal display value and calculated value)

● Tensile stress ● Tensile strength

● Breaking strength ● Elongation at break

● Constant tensile stress ● Constant stress elongation rate

● Fixed stress value ●

● Force value at any point ● Elongation at any point

● Extraction force ● Adhesion force and peak value calculation

● Pressure test ● Shear force peeling force test

● Bending test ● Pulling force puncture force test

Maintenance methods and precautions:

1. The surface of the machine should be regularly wiped and kept clean.

2. Please wipe the electroplating part with engine oil to prevent rust and maintain brightness.

3. Please add lubricating oil to the power screw and screw parts to ensure sensitive transmission. (Add a little engine oil to the lubricating oil and mix it with butter.).

4. Please wipe the panel (control box or monitor) with a dry cloth to prevent water contamination and prevent damage to IC electronic components.

5. All fixtures and joint accessories should be properly placed and wiped with rust proof oil to prevent rusting.

6. It is necessary to turn off the power when going to and from work.

服务

1.供方质量保证体系严格按照ISO9001质量标准之要求执行

2.培训:可根据客户要求在设备出厂前或设备到场后,对需方的技术人员进行操作、保养及设备维护进行技术培训

3.服务:当设备因质量或其他原因不能正常工作时,我公司在得到通知后24小时内给予答复;需要现场维修时,我公司在得到通知后48小时内派员上门维修、检测

4.设备保修期为1年。