地址:北京市海淀区上地十街1号

电话:15132636097

试验原理

毛细管流变仪测试的基本原理是:设定一个无限长的圆形毛细管中,塑料熔体在管中的流动为一种不可压缩的粘性流体的稳定层流流动;由于流体具有粘性,它必然受到来自管壁与流体方向相反的作用力。通过粘滞阻力应与推动力相平衡等流体力学过程原理的推导,可得到管壁处的剪切应力和剪切速率与压力、熔体流速的关系如下:

材料流经毛细管时的剪切应力为:

τ=R·⊿P/2L

(1)

其中 R—毛细管的内半径,这里 R=0.635 mm

⊿P—材料流经毛细管的压力差kg/cm2

L—毛细管的长度,例如选择长径比为30:1的毛细管,L=38.1mm

剪切速率为: ![]() =4Q/πR3

=4Q/πR3

(2)

其中 Q—挤出流量cm3/s

由此,在温度和毛细管长径比(L/2R)一定的条件下,测定不同的压力下塑料熔体通过毛细管的流动速率Q,由流动速率和毛细管两端的压力差⊿P,可计算出相应的剪切应力和剪切速率,将一组对应的τ和![]() 在对数座标纸上绘制流动曲线,即可求得非牛顿指数(n)和熔体的表观粘度(ηa);改变温度或改变毛细管长径比,则可得到代表粘度对温度依赖性的粘流活化能;以及离模膨胀比等表征流变特性的物理参数。

在对数座标纸上绘制流动曲线,即可求得非牛顿指数(n)和熔体的表观粘度(ηa);改变温度或改变毛细管长径比,则可得到代表粘度对温度依赖性的粘流活化能;以及离模膨胀比等表征流变特性的物理参数。

1、启动操作应用软件。

2、输入实验报告信息。

3、添加数据文件及输入实验参数,进行试验操作。

4、筛选数据。查看筛选的数据,检查数据的有效性和合理性。

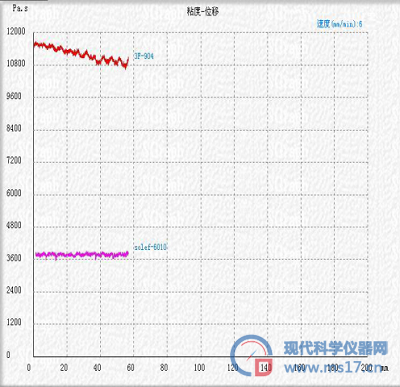

5、显示曲线,显示数据。

6、试验结束,打印保存数据及曲线。

7、关闭系统。

设备功能及特点:

1、毛细管流变仪流变仪为计算机测控智能化恒压式毛细管流变仪,能在恒压下和恒速度下工作,通过计算机测定各种压力作用下的各种规格毛细管在不同的升温速率下、不同温度时的挤出速度。通过计算机,记录挤出速度、压力和加热温度。自动处理成粘度数。并绘制曲线,打印完整报告单。

2、毛细管流变仪为测定高分子材料的流动性和固化速度。测定高分子材料熔体的粘度及粘流活化性,还能进行研究熔融纺丝的工艺条件。

3、毛细管流变仪可以测定高聚物的软化点、熔点、流动点、粘度粘流活化能,热固性材料的固化温度等性能指标。

4、控温系统及控制方式性能优越,利于测定不同温度下高分子材料的变化及相关性能。此仪器用计算机控制并绘制试验曲线,显试时时曲线变化,并得出的agen-poiseuille、Rabinowitsch、melt flow rute等方程数据。

5、毛细管流变仪采用负荷加载,设计合理,计算机控制并实现负荷连续加载,控制精度高,稳定性能好。毛细管流变仪可绘制高分子材料的应力应变曲线、塑化曲线,测定软化点、熔融点、流动点的温度。并绘制曲线,打印完整报告单。

主要技术参数:

型号 BML-400

A. 最大试验容量 5kN 10kN

B. 测试速度 0.005-20 mm/min

C. 负荷测试精度 ±0.5%

D. 负荷分辨率 100000码

E. 位移精度 ±0.5%

F. 变形精度 ±0.5%

G. 变形分辨率 0.01mm

H. 动态速度比 1:40,000

I. 最高测试温度 400°C

J. 温度控制 PID 控制,解析度0.1°C,误差度<±O.5°C

K. 升温速率 1-10℃/min,连续可调,并可快速升温

L. 控温精度 显示<±0.5℃

M. 温度分辨率 0.1℃

N. 料筒直径 11.28 mm :15mm:9.5 择一

O. 加热料筒长度 200 mm

P. 料筒材质 碳化钨

Q. 测试膛 电子加热测试膛,抽换式料筒

R. 压力传感器 容量择一 1000bar 700 bar 1400bar

S. 精度 < 0.25%

T. 材质 不锈钢、可抗腐蚀、耐高温

U. 毛细管 口膜材质 碳化钨

V. 尺寸(L/D) 5/0.5、10/1、20/1、40/1mm

W. 塞头直径 φ11.28 -0.012mm-0.05mm

X. 塞头面积 1cm2

Y. 测试模式 恒速、恒压、等模式

Z. 控制软体 BML 系统

AA. 电源 220V,50/60Hz,8A

AB. 重量 180 kg

配置名称 数量

(1) 试验主机 一套

(2) 高精度控温表 一块

(3) 进口伺服控制系统 一套

(4) 进口伺服电机 一台

(5) 数据采集系统 一套

(6) 数据处理系统 一套

(7) 高精度传感器 一只

(8) 专用出料模口

(9) 5/1、10/1、20/1、40/1mm(标配) 各一件

(10) 专用口膜托件 一只

(11) 品牌计算机 一套

(12) 彩色喷墨打印机 一台

(13) 专用试验软件 一套

A capillary rheometer can measure the softening point, melting point, flow point, viscosity and viscous flow activation energy of polymers, as well as the curing temperature of thermosetting materials and other performance indicators. These data play an important role in studying the rheological properties of polymers.

Experimental principle

The basic principle of capillary rheometer testing is to set an infinitely long circular capillary tube, where the flow of plastic melt in the tube is a stable laminar flow of incompressible viscous fluid; Due to the viscosity of the fluid, it is inevitably subjected to forces from the pipe wall in the opposite direction of the fluid. By deducing the principles of fluid mechanics processes such as the balance between viscous resistance and driving force, the relationship between shear stress and shear rate at the pipe wall, pressure, and melt flow rate can be obtained as follows:

The shear stress when the material flows through a capillary tube is:

τ= R · Δ P/2L

(1)

Where R is the inner radius of the capillary tube, where R=0.635 mm

Δ P - Pressure difference of material flowing through capillary tube, kg/cm2

L - The length of the capillary tube, for example, when selecting a capillary tube with a length to diameter ratio of 30:1, L=38.1mm

The shear rate is:=4Q/π R3

(2)

Where Q - extrusion flow rate cm3/s

Therefore, under certain conditions of temperature and capillary length to diameter ratio (L/2R), the flow rate Q of plastic melt passing through the capillary under different pressures can be measured. based on the flow rate and the pressure difference Δ P at both ends of the capillary, the corresponding shear stress and shear rate can be calculated. A set of corresponding τ By plotting the flow curve on logarithmic coordinate paper, the non Newtonian index (n) and the apparent viscosity of the melt can be obtained( η a) ; By changing the temperature or the length to diameter ratio of the capillary, the viscous flow activation energy representing the temperature dependence of viscosity can be obtained; And physical parameters that characterize rheological properties, such as the expansion ratio of the mold.

Data processing

1. Start the operating application software.

2. Enter experimental report information.

3. Add data files and input experimental parameters for experimental operations.

4. Filter data. View the filtered data and check its validity and reasonableness.

5. Display curves and data.

6. After the experiment is completed, print and save the data and curves.

7. Turn off the system.

Equipment functions and characteristics:

1. The capillary rheometer is a computer-based intelligent constant pressure capillary rheometer that can operate at constant pressure and speed. It measures the extrusion speed of various specifications of capillaries under various pressure conditions at different heating rates and temperatures through a computer. Record the extrusion speed, pressure, and heating temperature through a computer. Automatically processed into viscosity number. Draw the curve and print the complete report.

2. A capillary rheometer is used to measure the flowability and curing rate of polymer materials. Measuring the viscosity of polymer material melt